Sonderapplikationen

Aktuelles

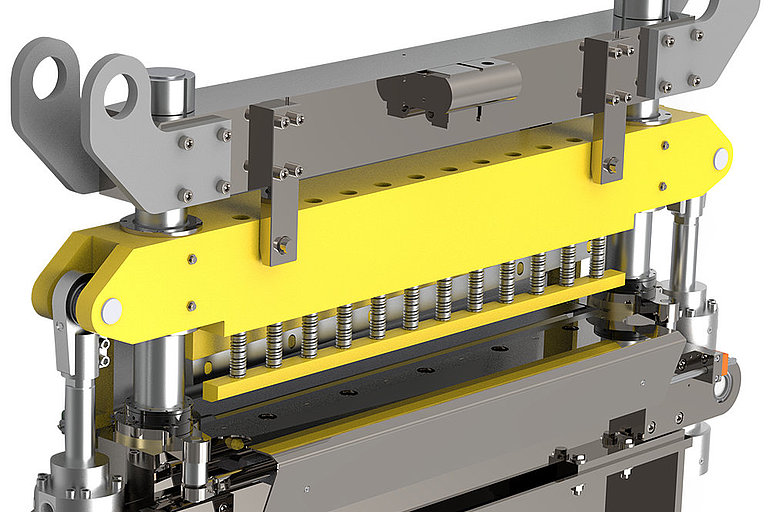

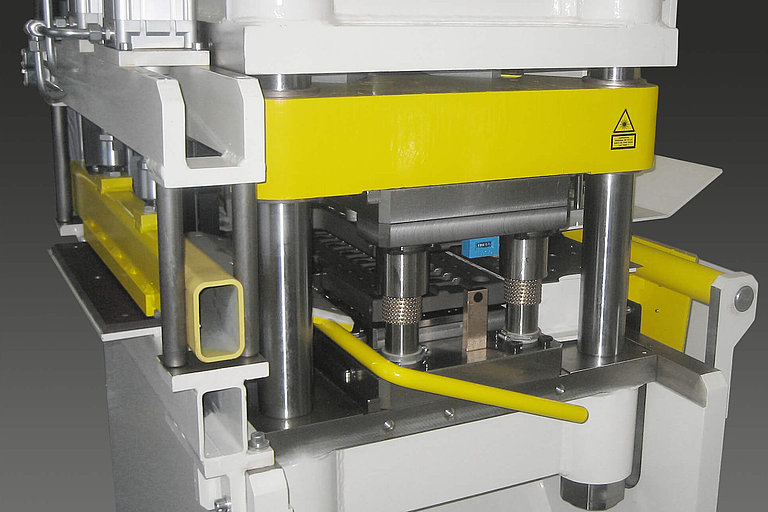

Scherenmesserwechsel in unter 1 Minute

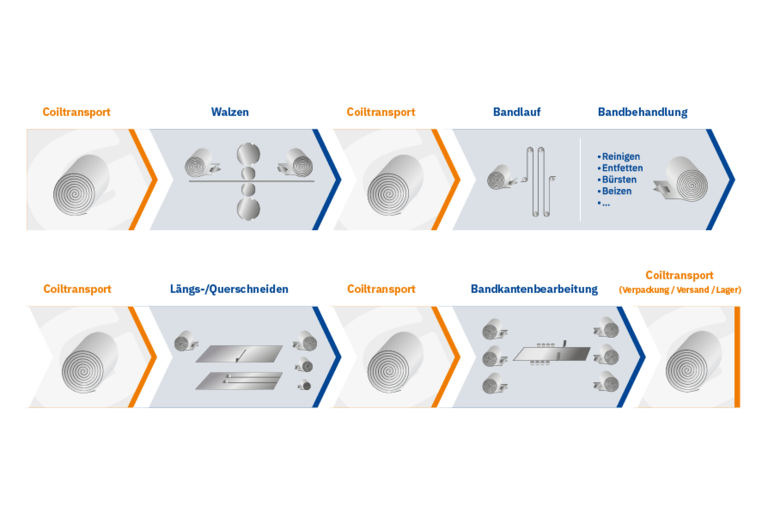

Produktionsstillstände bei Konti-Bandanlagen aufgrund eines unvorhergesehenen Scheren-Messerwechsels sind nicht nur kostspielig, sondern auch mit…

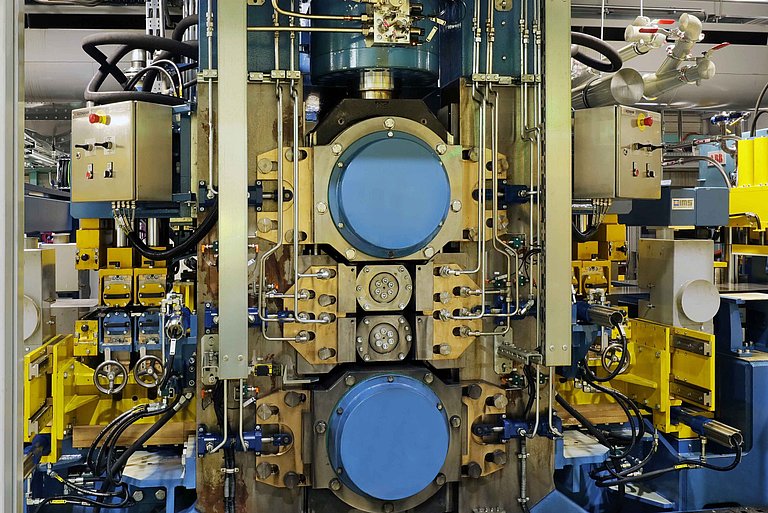

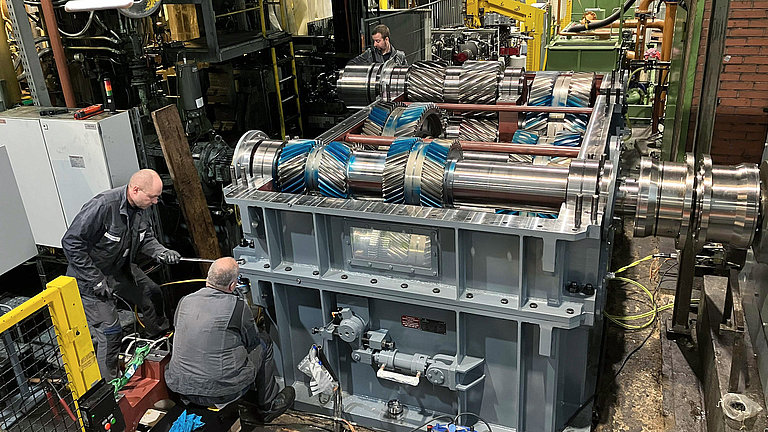

Mehrwert für die Stahlindustrie

Genkinger GmbH und hpl-Neugnadenfelder Maschinenfabrik GmbH bilden eine starke Partnerschaft innerhalb der Neuenhauser Gruppe und bieten für die…

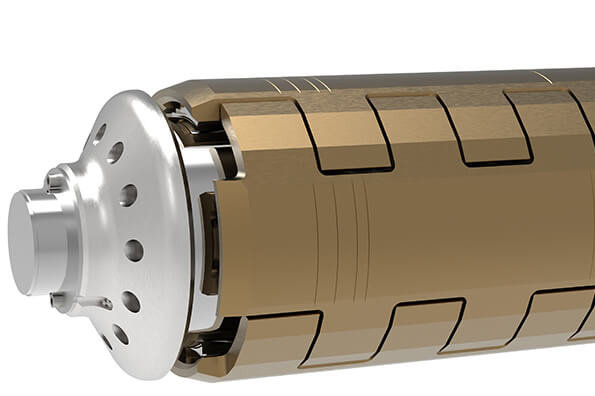

Konstruktionsdaten Klaus Bolender

Zeichnungen und Datenbestand von Klaus Bolender jetzt Eigentum der hpl-Neugnadenfelder Maschinenfabrik GmbH.

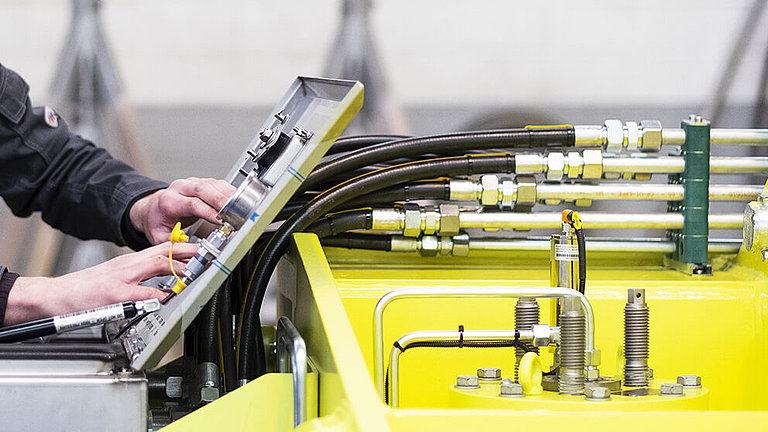

Stillstandzeiten beim Messerwechsel adieu!

hpl entwickelt neue Abtafelschere, die Stillstandzeiten signifikant reduziert und einen Messerwechsel in unter 1 Minute ermöglicht.